Biosolids and Wastewater Process Improvements

PROJECT OVERVIEW

The City of Auburn, New York, is moving forward with substantial improvements to the wastewater treatment plant (WWTP) on Bradley street. The City began planning for this project in 2019 with design commencing in 2020 and bidding for construction in Spring 2023. The project replaces aging WWTP infrastructure with a focus on improved biosolids processing capabilities to manage rising management and disposal costs. This project will improve the sludge thickening process, implement a digestion process to reduce sludge volume, and install a biosolids dryer and dry product storage area. This project also progresses Capital Improvements Plan (CIP) projects that will protect water quality and support WWTP effectiveness and reliability..

Coupling digestion with drying offers the following benefits: Reduces solids mass and dryer size and provides renewable biogas fuel to offset dryer energy requirements

- Creates a Class B biosolids product even when dryer is offline, increasing market and regulatory resiliency

- Creates a more stable, homogenous biosolids feed supply which improves dryer operation.

Operational costs for biosolids management consist primarily of the cost to haul and dispose of the wastewater solids. Historically, City of Auburn solids hauling and disposal costs have been approximately $400,000 per year. With the City landfill closure and landfill tip fees increasing across the region, the City has seen dramatically higher management costs. The Fiscal Year 2023 budget for solids hauling and disposal cost is over $1.5M, nearly quadrupling historical costs.

Digestion converts much of the solid organic matter into biogas, a renewable fuel source for heating the digesters and powering the dryer. This results in fewer solids to manage, and drying reduces the weight of the final material. These improvements will save the City well over a million dollars per year. There are also more outlets for dried biosolids, decreasing the management cost per ton as well as reducing risk.

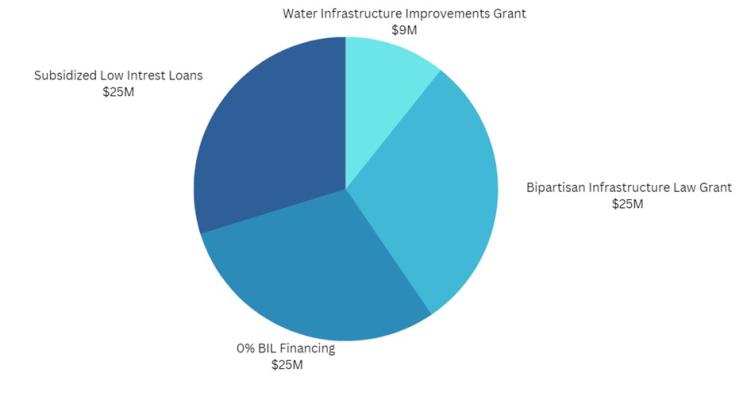

Project funding is provided by the New York State Environmental Facilities Corporation and administered by the New York State Department of Environmental Conservation, and managed by the City of Auburn staff. Project funding has been secured by multiple sources with $34M in grant funding secured. Below is a detailed breakdown of the project financing:

In addition to the funding presented above, the project will also be pursuing Inflation Reduction Act (IRA) funds due to the renewable energy infrastructure that is being installed at the WWTP under this project. IRA reimbursements, similar to grants, could cover as much as 30% of the biogas-related project costs.

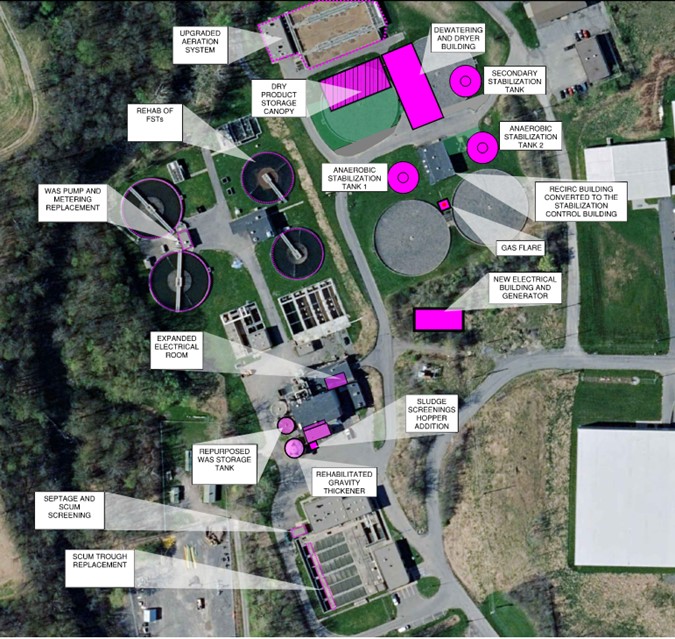

The figure below highlights the areas where process improvements are being completed at the WWTF. Areas shaded in purple indicate new facilities and areas outlined in dashed purple lines indicate existing facilities that are being improved/enhanced.

Contracts have been awarded to M. A. Bongiovanni Inc (General Contractor - Syracuse, NY), O’Connell Electric Company (electrical Contractor – Victor, NY), Siracusa Mechanical Contractors Inc. (Plumbing Contract – Auburn, NY), and King and King Mechanical Inc. (HVAC Contractor – Auburn, NY). Design engineering and construction oversight is being provided by Brown and Caldwell (Syracuse, NY).

February-March 2024 Project Update

The General Contractor (M.A. Bongiovanni, Inc.) completed trough repairs and reset weirs in all Primary Settling Tanks (PSTs); installation of scum skimmers in PST #3; completed concrete demolition in the Digester Control Building (DCB); placed concrete deck at the Solids Handling Building (SHB) feedstock tanks; restored storm piping that was removed due to conflicts with the 10” filtrate (FLT) pipe; continued 12” overflow (OF) piping towards the digesters; shaped stone/placed insulation for Primary Digester (PD) #1 and the Secondary Digester (SD); placed rebar and the concrete sump base in PD #1; placed concrete encasement for cooling water (CW) and digester sludge (DS) piping at the Dryer and Dewatering Building (DDB); placed and compacted stone inside the DDB; placed concrete wall infills and the 8” wall inside the DCB; completed startup/training for scum skimming equipment and septage receiving equipment; placed 10” concrete perimeter haunch, bottom mat of rebar, and installed embeds for PD #1; continued installing 6” 3W (non-potable water) piping towards DCB/DDB; began coring pipe penetrations in the north wall of the DCB; placed feedstock tank south wall infills; placed PD#1 slab; installed 90% of the 1W (potable) piping to the DCB; removed blower #4 from the aeration building; finished tubing/rebar/formwork for the SD and placed the slab; installed 6” DS lines from DCB to ST 2+60; excavated/shaped stone for PD #2; finished concrete wall cuts and concrete demo in the SHB basement; installed rebar and water stop in the south wet well of the DCB for floor infill; installed shoring/falsework for the 2nd story beams of the DDB.

The Electrical Contractor (O’Connell Electric Company, Inc.) finished power and controls for the septage receiving equipment including control panel relocation; removed existing gravity belt thickener control panel and associated conduits; finished cote drilling in the solids handling building basement for branch conduit pathways; finished final connections to last two scum pipe actuators; continued installing feeder/branch conduit in the blower building; continued installing branch conduit in the SHB basement; finished field investigation for arc flash coordination study; provided start-up for the scum pipe actuators and septage receiving equipment; relocated the variable frequency drive (VFD) cabinet for the post aeration blower #2.

The Heating, Ventilation and Air Conditioning (HVAC) Contractor (King & King Mechanical, Inc.) has not yet mobilized to the project site and continues to prepare submittals for engineering review and coordinate activities in master project schedule.

The Plumbing Contractor (Siracusa Mechanical, Inc.) mobilized to complete some floor drain and related piping in the DDB; continues to prepare submittals for engineering review; and coordinate activities in master project schedule.

The Project Engineer (Brown and Caldwell) continues to review contractor shop drawing submittals, address requests for information (RFIs), provide inspection services and general construction administration services.

The Contractors, Engineer, and City staff met on February 14, February 28, March 13, and March 27 for Construction Progress and Coordination Meetings. The Project is on schedule and on budget.

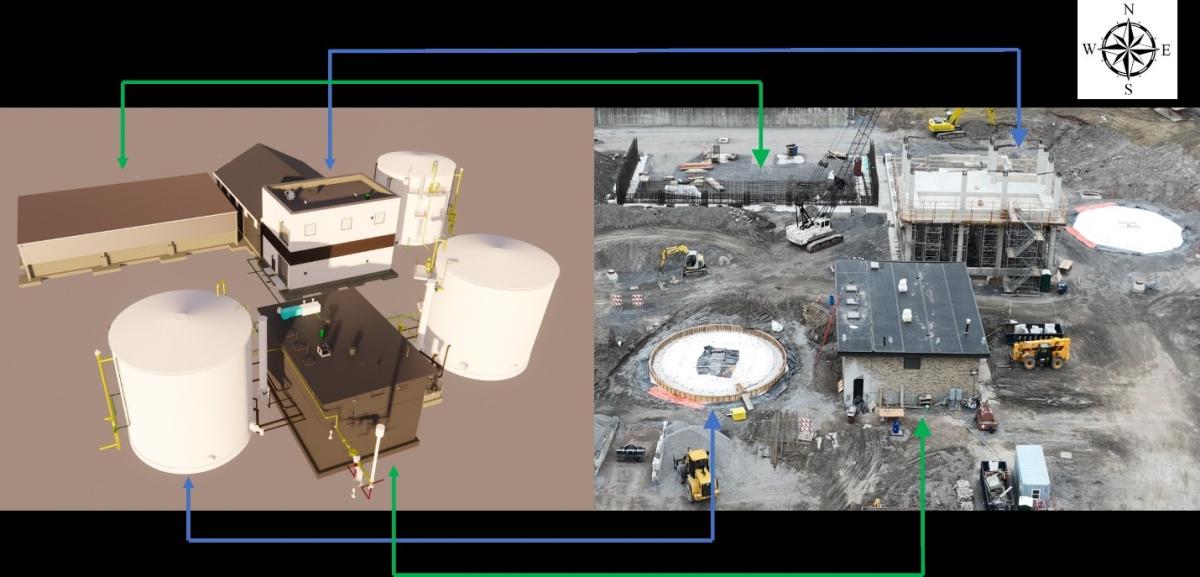

Project Construction Photos:

ABOVE: Construction Site Progress over Last Year

ABOVE: Building Model taking shape in the field

ABOVE: Site Photo February 11,2024

Please click here for the full February-March 2024 Project Update Report

January-February 2024 Project Update

The General Contractor (M.A. Bongiovanni, Inc.) placed flowable fill in abandoned pipes beneath proposed Primary Digester (PD) #1; installed bypass piping to enable reconfiguring Primary Effluent (PE) yard piping, transferred flow by installing a line stop, and after completing the yard piping work – removed line stop and bypass piping; backfilled PE force main connections and bypass saddles; excavated/established subgrade for PD #1 slab and began shaping stone subgrade; installed Digester Sludge and Cooling Water (CW) piping under slab piping at the Dewatering and Dryer Building (D&DB), formed encasement and installed rebar; continued installing 12” digester Overflow piping; installed a portion of 6” CW and 4” drain piping towards the cooling tower; and completed abatement and pipe demolition in the Digester Control Building (DCB).

The Electrical Contractor (O’Connell Electric Company, Inc.) started and finished pulling underground feeders:

Electrical Manhole EMH-1B to EMH-1 = 11 Sets

EMH-1B to Dog House = 3 Sets

EMH-1D to EMH-1G = 14 Sets;

continued and finished installation of branch conduit and 480V wiring to the scum pipe actuators, and installed new buckets in Motor Control Center MCC-7; started core drilling in the Solids Handling Building (SHB) basement for the SHB-MCC feeder conduit, and started running feeder/branch conduit; and started branch conduit for the Septage Receiving Station equipment upgrade.

The Heating, Ventilation and Air Conditioning (HVAC) Contractor (King & King Mechanical, Inc.) has not yet mobilized to the project site and continues to prepare submittals for engineering review and coordinate activities in master project schedule.

The Plumbing Contractor (Siracusa Mechanical, Inc.) has not fully mobilized to the project site and continues to prepare submittals for engineering review. They anticipate weekly site visits for contractor coordination purposes.

The Project Engineer (Brown and Caldwell) continues to review contractor shop drawing submittals, address requests for information (RFIs), provide inspection services and general construction administration services.

The Contractors, Engineer, and City staff met on January 10 for the Monthly Construction Progress and Coordination Meeting, and on January 24 for the Mid-Month Progress and Coordination meeting. The Project is on schedule and on budget.

Please click here to view the full January-February 2024 Project Update Report

December 2023 Project Update

The General Contractor (M.A. Bongiovanni, Inc.) placed beams and slab at 2nd story of the Dewatering and Dryer Building (D&DB), continued concrete and masonry demolition in the Digester Control Building (DCB), demolished existing scum skimmers in Primary Settling Tank (PST) #1, demolished existing septage receiving equipment, restored two (of three) storm piping connections that had been disrupted by newly installed process piping, installed and tested piping between manhole FLT-5 and FLT-6, tested 36” ductile iron pipe (DIP) for the new force main, installed a portion of 12” overflow (OF) pipe to primary digester (PD) #1, placed sloped concrete fill in the feedstock tanks and installed falsework for the suspended slabs above.

The Electrical Contractor (O’Connell Electric Company, Inc.) received the first wave of feeder wire deliveries (36 reels), and continued branch conduit for scum pipe actuator power and controls.

The Heating, Ventilation and Air Conditioning (HVAC) Contractor (King & King Mechanical, Inc.) has not yet mobilized to the project site and continues to prepare submittals for engineering review.

The Plumbing Contractor (Siracusa Mechanical, Inc.) has not fully mobilized to the project site and continues to prepare submittals for engineering review. They anticipate weekly site visits for contractor coordination purposes.

The Project Engineer (Brown and Caldwell) continues to review contractor shop drawing submittals, address requests for information (RFIs), provide inspection services and general construction administration services.

The Contractors, Engineer, and City staff met on December 13th for a monthly Construction Progress and Coordination meeting. The Project is on schedule and on budget.

Please click here to view the full December 2023 Project Update Report

November 2023 Project Update

The General Contractor (M.A. Bongiovanni, Inc.) installed shoring and decking for the second story of the Dewatering and Dryer Building (D&DB), while formwork, reinforcing steel, pipe sleeves and other appurtenances are being placed in preparation of upcoming concrete pour. They also: removed existing concrete slab and began placing wall infills, slope concrete infill, and suspended slab replacement south of the feedstock tanks; installed 6-inch non-potable effluent water (3W) piping from Settled Sewage Pump Station and made connection up to the north branch line; continued to install 18-inch overflow (OF) piping and 36-inch primary effluent (PE) piping; removed top of the final settling tank (FST) diversion structure and began setting forms and placing reinforcing steel for future concrete pour. Concrete and masonry demolition continued on the Digester Control Building (DCB).

The Electrical Contractor (O’Connell Electric Company, Inc.) completed installation of duct banks C1, N8, P1/P2; installed the direct buried fiber conduits to the Maintenance Building (MB); installed racking, grounding and pull lines in all new manholes; and provided preliminary site restoration at the existing and new substation locations. They are currently working on the under slab conduits for the D&DB building motor control center (MCC); installation of ground grid for the D&DB and Dry Product Storage Building (DPSB); demolish the existing feeders for the previously removed MCC-12 and proof conduits for reuse; and start branch conduit for new lighting in the Solids Handling Building (SHB).

The Heating, Ventilation and Air Conditioning (HVAC) Contractor (King & King Mechanical, Inc.) has not yet mobilized to the project site and continues to prepare submittals for engineering review.

The Plumbing Contractor (Siracusa Mechanical, Inc.) has not fully mobilized to the project site however has been providing and coordinating locations for sleeves in floor slabs/decking for installation by the General Contractor. They anticipate weekly site visits for contractor coordination purposes.

The Project Engineer (Brown and Caldwell) continues to review contractor shop drawing submittals, address requests for information (RFIs), provide inspection services and general construction administration services.

The Contractors, Engineer, and City staff met on November 8th for a monthly Construction Progress and Coordination meeting. The Project is on schedule and on budget.

The above video takes a virtual tour of the project site (October 7, 2023)

Dewatering and Dryer Building: Second story taking shape on left; foundation walls on right

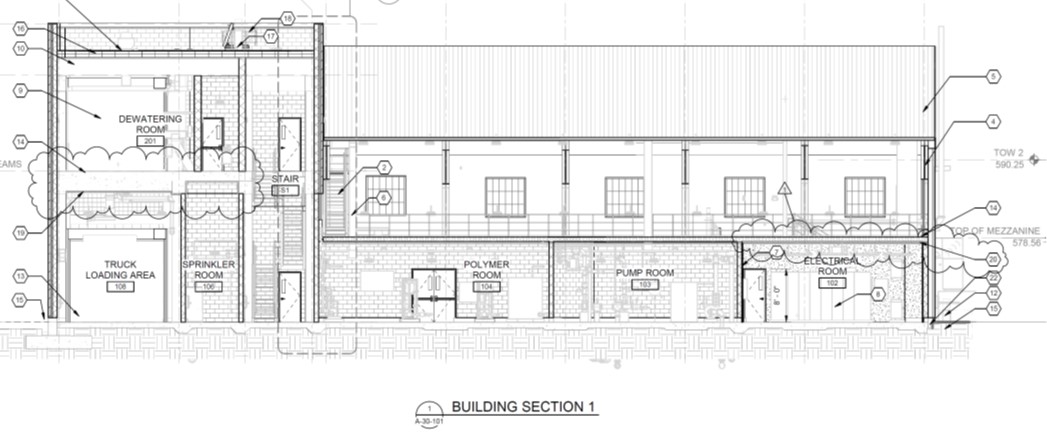

An architectural section of the D&DB shown in photo above

Electrical duct banks in vicinity of proposed Electrical Substation, Generator, and Transformer

October 2023 Project Update

October 13, 2023 Project Update: Site work continues to progress and setting of new infrastructure to support the new and updated facilities. Contractors have continued placing electrical duct banks, placing of buried piping, rehabilitation and abatement of existing facilities for future use, and demolition of existing facilities. Foundations and columns are being established for the new biosolids digester and drying facility. Concrete work for new dewater sludge facilities has also progressed. The Contractors, Engineer, and City staff met for the 7th monthly Construction Progress and Coordination meeting.

Please click here to view the full October 2023 Project Update Report